As another high-profile cyber-attack makes the news, many of us guiltily breathe a quick sigh of relief that it’s not us.

In 2020, cyber-attacks in manufacturing accounted for more than 30% of all incidents (Source: PMMI). During the same period, Australian manufacturing businesses accounted for 13 per cent of all known attacks.

Although many in the industry are aware of the benefits IIoT tools can have on an organisation, connected systems can be a potential gateway for cyber breaches. That means system security can be a major sticking point that unnecessarily holds up transformation projects.

We know that cyber security risks do need to be managed as the industry shifts to greater technology adoption and connectivity. But, like all developments in technology, there’s a balance to be struck between connectivity and risk.

A 2019 survey by PWC showed that 93% of executives believe the benefits of IoT outweigh its risks, and after the pandemic, there’s even more evidence adopting IoT and digital tools can preserve revenue streams and enable manufacturing to bounce back.

Managing cyber security risks doesn’t mean pausing your digital journey

A recent ransomware attack impacted the supply chain for large-scale manufacturers such as Tesla and Boeing, using the data as leverage.

Earlier this year, a cyber security attack on a fuel network led to the company shutting down operations while they worked to resolve the issue. With the network supplying half of the East Coast in the United States, this disruption led to a prolonged 5-day shutdown, fuel supply issues and a huge spike in costs to the consumer.

These incidents naturally leave a lot of organisations feeling uneasy about the risk of having critical operational information locked down or sensitive company data and IP encrypted while the business is held to ransom or forced to stop operations.

Unfortunately, that worry can also be a barrier that leads to an underestimated cost – missing out on the insights of connected data from across your business – which drive improved manufacturing outcomes.

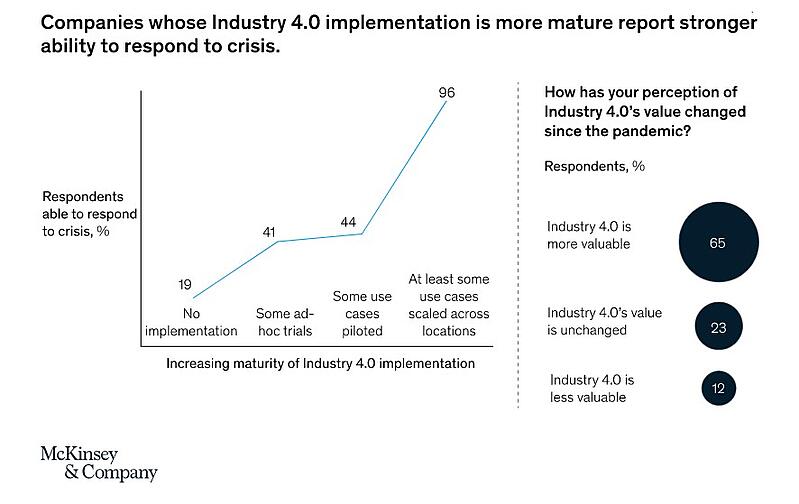

A global pandemic highlighted digital technologies as an enabler, with findings from a McKinsey survey showing 94% of companies who had scaled their digital transformation were able to keep operating during the crisis. These companies found themselves positioned to respond to issues better during the crisis.

Above: McKinsey survey results showed that companies that scaled Industry 4.0 use cases before

the global pandemic were able to respond better to the crisis.

How do we continue with digital transformation projects and be mindful of cyber security risk?

At a bare minimum, we should all be following cyber security best practices and using our own security measures to ensure we’re managing critical systems against risk.

Results from the 2019 Deloitte and MAPI Smart Factory Study showed that 24% of companies don’t perform annual cyber risk assessments. Undertaking these assessments, encouraging all employees to maintain good ‘cyber hygiene', and following best practices do help to reduce the threat of a cyber-attack.

This includes having a risk management program in place that considers your technology vendors and partners. Making sure your partners are following cyber best practices, and that they keep their skills up-to-date, is an important way to protect your business.

Above: In 2020, team members from Nukon and the wider SAGE Group took part in an online security challenge, facing the

type of question an IT/OT analyst regularly deals with - and placing in the top 30% of the competition!

Back in 2017, we first shared some simple cyber best practices your business can undertake, and we've been updating the items on that list to ensure it holds true today.

Other security steps to take:

- Consider system security before designing/implementing IoT initiatives

- Install security updates as quickly as possible

- Determine responsibilities for monitoring security gaps

- Continually reassess your in-house practices for data and system security.

Manufacturing, the cloud and cyber security

For those manufacturers still feeling unsure about diving into IT-OT convergence and the risks of connecting their systems, another option is cloud solutions.

Manufacturers currently relying on on-premises data storage may find virtual data centres, and the shared security models of cloud providers more attractive. 2020 was the first year that enterprise spending on cloud infrastructure surpassed spending on data centre hardware and software.

Amazon Web Services (AWS) is probably one of the most well-known in terms of cloud vendors, and their shared security model attracts many manufacturers looking to mitigate risk, particularly for SMEs who don’t have a dedicated cyber expert on staff.

Using cloud-based systems offer the benefit of streamlined updates for vulnerabilities, making it easier to secure than on-premises solutions where someone needs to manually patch to minimise a breakdown.

Keeping an isolated backup of files in the cloud also provides the reassurance that manufacturers can resume operations faster in the event of an incident. A bonus of cloud solutions is they can facilitate smoother scalability and faster development, and cloud cyber security capabilities are constantly evolving.

Why the benefits of connected factories outweigh the risks

Most industrial environments weren’t designed with today’s connected solutions in mind, but the manufacturing industry has become good at adapting.

There really is no value to come from delaying digital transformation and your organisation’s digital aspirations to protect yourself against a cyber incident. No business can declare itself 100% protected. Instead, manufacturers must consider implementing defensive measures to provide the best levels of protection.

This is where experienced integrators can be hugely valuable – they can help you make informed decisions regarding your integration and work with you to build the required security services into your solution.

Nukon design IIoT-enabled solutions with cyber security as a number one priority. Learn more about the opportunities of connected systems with our cheat sheet.