This PaaS solution harnesses cloud technologies to provide more data and seamless customer experience for recycling depots.

This PaaS solution harnesses cloud technologies to provide more data and seamless customer experience for recycling depots.

Food and Beverage

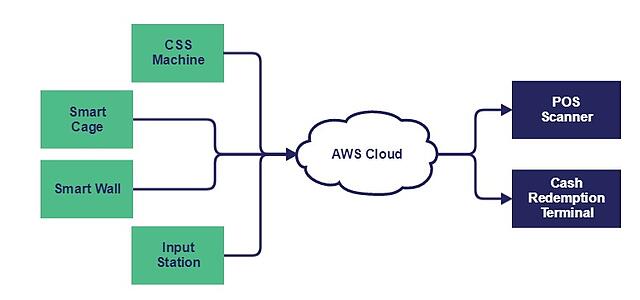

A series of automated container sorting, counting and cashier systems have transformed the customer experience for recycling depots. The IoT cloud solution improves throughput, counting accuracy, and reduces operating costs through savings in data and IT infrastructure.

Internet of Things (IoT), Amazon Web Services (AWS) cloud solution, elastic computing, Platform as a Service (PaaS), and solution design, testing and implementation for a unique pilot project

Australia-wide

It’s no surprise that South Australia has the lowest percentage of containers-to-landfill in the country – it was the country’s first state to adopt Container Deposit Legislation (CDL) back in 1977. In 2016, over 43 million tonnes of containers were saved from landfill with $58 million refunded to individuals and community groups. The CDL scheme employs 5,000 people across a network of 125 depots.

But the state’s recycling depots still count and sort containers manually – a process that’s remained unchanged for the last 40 years. The associated challenges are:

This manual process has been one roadblock in the logistics of a national uptake of CDL.

Alternative solutions, such as the European reverse vending machines on the market, only accept and scan containers with intact barcodes – and one at a time. Anything slightly damaged or with no label cannot be refunded. It was clear an alternative solution was required.

Dreaming up a solution

With years of experience in the industry, the shareholders and founders of Container Deposit Systems (CDS) were well aware of the long-standing challenges. So it designed its solutions specifically to enable a nationwide uptake of the recycling refund scheme. With this in mind, CDS approached sister companies SAGE Automation and Nukon to help...

They developed three automated sorting, counting, data collection and processing solutions:

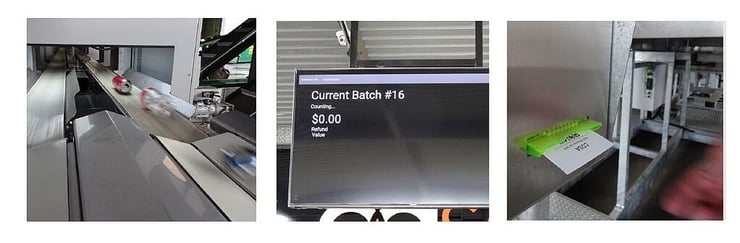

1. Bulk Redemption Terminal (BRT) formally the Counting and sorting system

An automated conveyor and smart vision system, developed with UniSA, rapidly sorts and counts the containers. The system calculates the refund amount based on the container count and produces a refund receipt for the customer. All data is saved to the cloud for reporting.

2. Auto Return Terminal (ART)

A semi-automated, containerised counting and sorting system. ART uses the BRT's vision system to identify containers and sort them, even if they are damaged. Can be deployed anywhere via shipping container. Automatically generates receipt for cash refund and dispenses cash via a secure Cash Redemption Terminal

3.Manual Input Station (MIS)

A very simple user interface that enables depot operators to count and process refund transactions electronically – bringing higher probity of information. Automatically prints the redemption receipt for immediate cash refund. Data is saved to the cloud for reporting and transparency. Transactions can be synced to CCTV to prevent fraud or review customer interactions.

Cash Redemption Terminal (CRT)

All three systems can be used separately or in conjunction across multiple depots. All offer cash back via either an operator controlled PoS system or Cash Redemption Terminal. Together they provide fast, accurate and cost effective alternatives to existing systems.

Nukon customer facing solution: Single-Board Computers, AWS, Encryption

SAGE control system solution: Beckhoff control, NORD drives

What’s exciting about this solution is how the technology has been developed and deployed as Platform as a Service (PaaS).

The entire customer-facing solution uses small, low cost computers and Amazon Web Service’s powerful cloud based architecture. The system connects with secure closed networks and PLCs if required.

“We can set up 5-6 devices for less than cost of a desktop computer,” Nukon Senior Consultant Damian Jolly explained. “We’d never be able to do this with traditional technologies so this shows how the IoT is changing our world – from manufacturing to recycling and beyond,” he said

As sister companies, SAGE and Nukon worked together with research and technology providers to deliver this integrated solution.

While SAGE delivered the CSS controls system, conveyor lines and vision system in partnership with UniSA, Nukon took care of the IT and customer-facing solution.

Agile project delivery reduced the development costs by giving the client multiple opportunities to change their requirements as needed.

“We used a prototyping model, which means the clients gets something in their hands quickly so they can tell us what works and what doesn’t,” Nukon Senior Consultant Damian Jolly explained.

“’We also chose to standardise on the IoT methodology. And because we used the same platform and hardware we could reuse a lot of functions, which meant we could refine it, react, and ultimately save CDS a lot in development costs.”

The standardised approach also future proofs the solution and allows rapid scalability.

The BRT, ART and MIS each provide an answer to the recycling depot industry’s pain points.

The solutions each give depot:

Features and benefits include:

• Smart — Unlike reverse vending machines, the ART and BRT do not rely on intact labels to identify container type.

• Accurate — The vision system accurately sorts and counts containers by type. The system provides daily and historical reports, depot performance, material amounts, and links to CCTV to deal with customer complaints.

• Low cost — Single-board computers and cloud-based IT infrastructure is cheap to implement, run and store. Elastic computing with AWS eliminates need for costly servers onsite and reduces payments for hosting offsite.

• Agile — IT infrastructure allows Nukon to deploy new code changes very quickly and set up new collection points in no time.

• Secure — Devices send messages over plain internet using encryption for high levels of security.

• Reliable — Never lose your data. AWS’s redundancy and backup practices are best in the world.

• Scalable — AWS provides unlimited data storage and computing power in a centralised cloud = no need for onsite hosting, rapid scalability at reduced costs.

The solution provides a viable business opportunity for container depots, both existing and new – all to help decrease Australia’s landfill.

“These solutions will dramatically improve the performance of container depots; especially in transforming the customer experience.” Brett Duncanson, Executive Chairman, CDS.

The full suite of CDS’s solutions will be available to other recycling depots over the next year.

Nukon transforms existing infrastructures, unifies business silos, and turns isolated data into actionable insights that help you thrive.