Cristal is one of the world’s largest producers of titanium dioxide (TiO2) and a leading producer of titanium chemicals.

The company builds innovative products that harness the unique functionalities TiO2 to create a cleaner and brighter future.

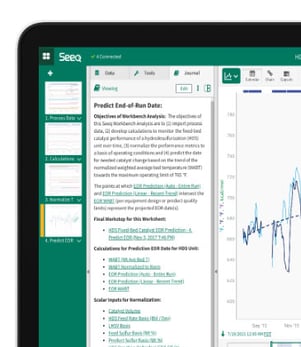

Nukon recently worked with Cristal and introduced Seeq, a process data analytics specialist and OSIsoft solution partner, to:

- Enable fast time-to-insight on time-series data

- Reduce the time spent in spreadsheets, and

- Improve processes to deliver better operational efficiencies.

Cristal wanted to have the ability to continuously improve their operations and achieve a better return on investment for their production facilities.

However, in order to meet this objective, the company realised that they needed to overcome two main challenges:

1. Improve the tools available to engineers and production team

Cristal needed better tools to analyse time-series data – that is, tools that delivered beyond what traditional tools could provide.

The company recognised the clear limitations of excel in analysing data and the need for a modern set of tools that enabled better process data analysis for incident investigations.

They also wanted to reduce the time spent on spreadsheets. This would greatly improve the speed of root-cause analysis – decreasing the time needed to understand production issues including start-ups and asset performance.

2. Gain valuable insight across processes and products

Cristal lacked production visibility across processes and products. For instance, they didn’t have enough information on the impact of different ingredients or different volumes of ingredients on the process.

Cristal needed to have a better understanding on why and how things were processed. They wanted to have the ability to reconstruct the conditions that led to a particular incident – and then be able to review historical data, validate assumptions and record the findings.

Cristal knew that all the data was there in the process-driven plants. However, they didn’t have the ability to use the data to gain valuable insights and confirm their hypotheses on root cause issues.