Unified Namespace (UNS) is a game-changer for industrial automation, providing a standardised approach to data sharing and interoperability between different systems and applications.

With the explosive growth of the Industrial Internet of Things (IIoT) and Industry 4.0, the need for seamless integration and connectivity across disparate systems has never been more important.

UNS offers a powerful solution to this challenge, enabling organisations to build a framework that promotes data consistency and accessibility while being scalable to suit any digital transformation.

In this blog, we’ll explore how UNS works, why it’s essential for digital transformation, and how you can get started on your UNS journey.

What is Unified Namespace?

Unified Namespace describes the practice of integrating consistent naming conventions across systems and applications in your organisation, creating a single source of truth for data across machines, equipment, and processes.

To understand how UNS works, we first need to learn its origins to understand where it fits as part of any digital transformation journey.

An evolution of the automation pyramid

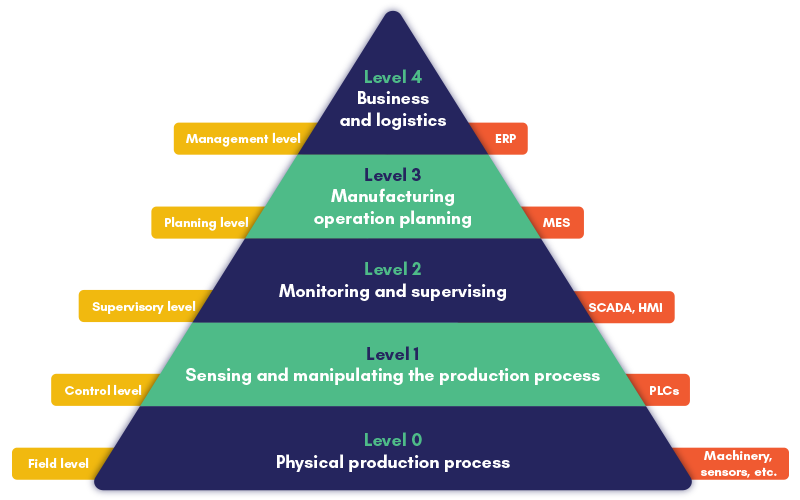

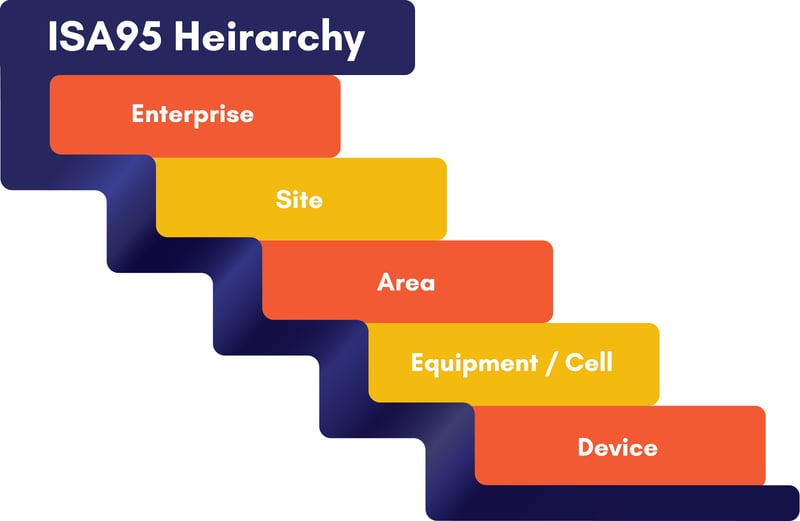

For more than 40 years, Industry 3.0 relied on the automation pyramid – a hierarchical model that encapsulates the levels of automation in industrial control systems – to inform the architecture of industrial automation systems.

Unified Namespace is an evolution of the automation pyramid (pictured).

Automation systems require data to travel through multiple levels to reach its destination, with each level having its own communication protocols, interfaces, and data life cycle. To break the data exchange barriers, industrial companies needed a common technology.

Message Queue Telemetry Transport (MQTT) protocol was the answer.

Emerging in 1999, the rise of MQTT came out of the need for a protocol that was bandwidth-efficient, lightweight and used very little battery power. The protocol operates on a publish/subscribe principle, requiring a central broker-node to forward received messages.

MQTT – The building block of UNS

Initially used for oil pipeline monitoring by devices connected via satellite link, many industrial hardware and software vendors implemented MQTT into their telemetry offerings due to the ease of adoption and open-source nature, allowing for customisation across industries.

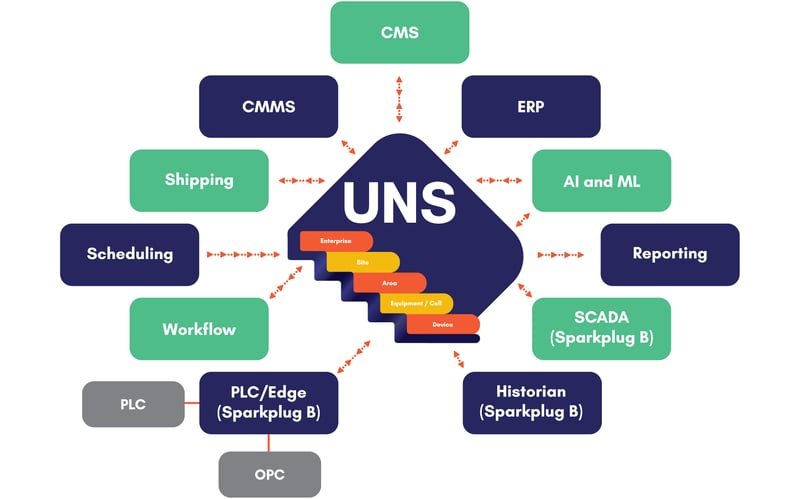

Today, common MQTT technology allows different levels of the pyramid to talk directly, converting data from disparate assets into a hub and spoke architecture, organising into a hierarchy of topics.

Each client (connected device or asset) can subscribe and/or publish to specific topics from the central hub or broker. When a publisher has a new item of data to distribute, it sends a control message with the data to the connected broker. The broker then distributes the information to any clients that have subscribed to that topic.

While MQTT is a communication protocol that enables devices to send and receive messages and distribute the data to other devices, the UNS sits on top of the MQTT to organise this data in a unified and consistent way across different systems and applications, helping to eliminate data silos and improve data integration across different applications and systems.

How does UNS work?

UNS works by creating a single, standardised naming convention for all data points in a system, allowing different systems to reference the same data points using a common name, regardless of the underlying hardware or software platforms.

In practice, UNS typically involves the use of a SCADA system or other IIoT platform to unify the different systems and devices in an organisation – primarily in manufacturing environments.

Through this integration layer, the data points from the different systems and devices are mapped to a singular data model (namespace), making it easy for different systems to access and use the data.

The hub and spoke architecture of UNS allows for smooth and unified data flow and analysis.

Data is organised within the UNS into the hierarchical model relevant to your industry. For example, the common framework in manufacturing is the ISA-95 Standard, the international standard for the integration of enterprise and control systems.

Interested in what UNS looks like in the real world? We explore this in detail in Unified Namespace Part 2: Real-world applications and challenges!

Understanding the ISA-95 Standard

While the automation pyramid is a more general representation of the hierarchy of automation systems in a manufacturing environment, the ISA-95 standard provides a more detailed integration framework.

UNS enables you to store, manage, and access data and resources across your entire enterprise via a centralised repository of information – and this is informed by the ISA-95 Standard hierarchy.

The ISA-95 Standard informs the hierarchy upon which to build a Unified Namespace.

The ISA-95 Standard informs the hierarchy upon which to build a Unified Namespace.

Other frameworks, such as the ISA-106 Standard – which provides guidelines for managing and optimising procedures in the process industries – are useful when implementing UNS across different industrial environments and modelling physical automation devices.

What is Sparkplug B?

Developed by Cirrus Link Solutions, the Sparkplug B specification is an open standard for data integration that enables seamless communication between sensors, devices or gateways and applications within an MQTT infrastructure. Sparkplug B is built on top of MQTT to enhance its capabilities, safeguarding against most challenges encountered in industrial automation and control systems, complementing UNS capabilities.

When implementing UNS, building Sparkplug B on top of your MQTT infrastructure safeguards against most challenges you’ll come across. Field devices or gateways should use Sparkplug B to standardise the payload and enable connection monitoring, which is not available via MQTT alone.

The Sparkplug B protocol was designed specifically for industrial IoT and machine-to-machine communication, offering significant benefits to large distributed systems and organisations with many telemetry-producing assets under management.

Some of the benefits of Sparkplug B include:

- Edge-driven configuration,

- Single source of truth for streaming data,

- Report by exception, and

- Event-driven integrations with more advanced applications.

A must-have for Industry 4.0

Implementation of Unified Namespace architecture has become a pre-requisite for integration of advanced technologies such as artificial intelligence, the Internet of Things, and big data analytics into manufacturing and industrial processes – which define Industry 4.0.

UNS also improves the Operational Technology (OT) security posture, because MQTT clients initiate an encrypted outbound connection instead of the classical Poll-Response model in which a firewall must permit inbound connections.

Enabling improvements to data sharing between industrial automation systems and reducing the complexity of integrating different systems and devices, UNS enables an array of benefits that support Industry 4.0.

The benefits of UNS include:

- Improved data and resource management,

- Increased consistency and reliability,

- Enhanced security,

- Simplified administration,

- Improved collaboration and communication,

- Broader operational visibility, and

- Better decision-making capabilities.

These benefits enhance your ability to implement cutting-edge smart manufacturing capabilities such as a Digital Twin enabling manufacturers to create virtual models of their production systems for predictive maintenance and optimisation.

However, while UNS has been hailed for its numerous benefits, there is still room for improvement in its implementation.

The limitations of UNS include:

- Dependency on standardised protocols,

- Implementation complexity,

- Security risks (single point of failure requires robust security measures),

- Compatibility issues, and,

- Investment of time, resources, and expertise.

We delve into all of this in more detail in Unified Namespace Part 2: Real-world applications and challenges!

Entering mainstream popularity through a series of YouTube videos by renowned IoT and Industry 4.0 expert, Walker Reynolds, the concept of Unified Namespace has seen growing adoption by small companies and large multi-national operations alike.

Unified Namespace closes the OT/IT gap more than ever before and should be considered essential to industrial digital transformation and Industry 4.0 implementations.

About the author

Sergey Koreshkov is a Senior Analyst and Tech Lead with Nukon. With more than 18 years of experience in the controls and automation of utilities, manufacturing, and processing industries, for the last several years, Sergey has been focusing on telemetry projects, process historian integration, cloud computing and IoT.

Sergey actively explores modern IT tools with potential in industrial applications, is passionate about developing integrations for classical automation systems, and brings new functionality into the automation world to support digital transformation business outcomes.